By Stathis Pothitakis, market manager, Mettler-Toledo Product Inspection

OPTIMISING production yield from a defined amount of raw ingredients is important for all manufacturers, but when you are creating more than three million individual products every day, it becomes critical.

The German chocolate brand Ritter Sport exports to more than 100 countries and knows that overfills from each of its products by just a single gram, increases the cost in raw material by about three tons every day.

With multiple production lines running, the goal is to optimise filling so that it is neither under- or over-filling its ingredients. The manufacturer takes a twin approach to checking its product weights: automatic checkweighers from Mettler-Toledo inspect specialty bagged products, while samples of square chocolate bars, that have just been pressed out of the moulding form, are taken from a belt by an operator at predefined time intervals, to be manually weighed on a Mettler-Toledo ICS bench scale.

Working at speed, the data gathered in these processes is collected and analysed in the FreeWeigh.Net statistical quality and process control software provided with the ICS bench scale. Ritter Sport can immediately determine, at the point of production, whether there has been any process deviation that requires an adjustment to be made. The operator is informed of the deviation and what adjustment is required, for a quick intervention.

As a major exporter, Ritter Sport has to comply with multiple national and international net content guidelines and global food standards. The use of Statistical Quality Control (SQC) with FreeWeigh.Net software is a key control that supports manufacturers in meeting compliance with these guidelines and standards.

What is SQC?

Defined as a statistical way of controlling quality parameters as well as processes, SQC utilises methods such as Statistical Process Control (SPC), which adopts sampling and statistics to monitor the quality of an ongoing process such as the production operation. The statistical analysis works by taking weight measurements of net content from a base number of samples and calculating the Standard Deviation – the level of variation between the sampled products.

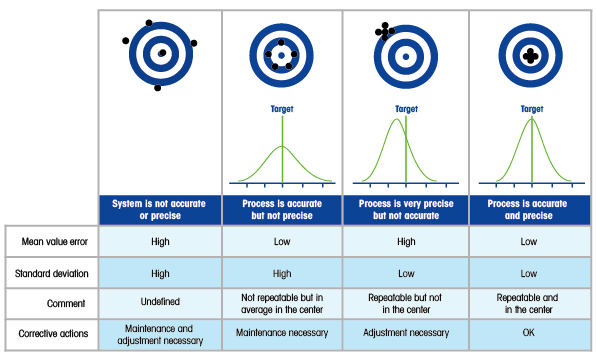

Of course, it helps if the weighing device is capable of providing weighing measurements that can be trusted. There are two key terms that define a systems performance: the accuracy and the precision. Though these may, at face value, seem to be the same thing, there is an important distinction between the two terms. Accuracy is the ability of the device to measure a known value, while precision is the ability of the device to repeat the same measurement consistently. As can be seen in the table below, ideally a weighing device should be both accurate and precise. If either parameter, or both, is lacking, then maintenance and adjustment may be required to establish consistent and meaningful measurement results.

Accuracy and Precision

Comparison

It is possible for food manufacturers to operate without statistical aids such as SQC, but doing so significantly increases the possibility of human error when using static scales to check net product content. In comparison, SQC enables the swift identification of any process deviation, and the consequent immediate adjustment of other production line parameters (on filling machines, for example) needed to bring performance back within Standard Deviation allowances.

SQC can be used with static scales (or “non-automatic weighing instruments”) that require a product to be manually placed, with time required for the weight to be calculated. It can also be used with “automatic weighing instruments” such as automatic scales and dynamic checkweighers that are installed on the line, and perform the weighing calculation as the product moves along the line.

Using weighing technology that is equipped with SQC/SPC-enabled software provides clear advantages over relying on a manual calculation of the Standard Deviation in a set of samples, as this table clearly illustrates:

| Scale without SQC | Scale with SQC | Checkweigher with SQC | |

| Automatic or manual recording of sample weights and Standard Deviations | Sample weights are recorded, and Standard Deviation manually calculated.

|

Samples are recorded from the scale which calculates the Standard Deviation and may provide operators with action signals.

|

Inline checkweighers do not need human intervention and automatically weigh every single product for quality checks. |

| Scope of statistical process | Statistical process with possibility of deviation from the actual status.

|

Statistical process with possibility of deviation from the actual status.

|

Automatically records weights and calculates very accurate standard deviation and filling trends.

|

| Speed of process | Slow process – time consuming with late “reaction” to improve or correct the process.

|

Interaction with production lines is much faster compared to software scales without SQC.

|

No human intervention. Checkweighers can be connected with the fillers and automatically perform required corrections.

|

| Data connectivity | Archiving documentation and batch release takes longer.

|

Can be networked and data stored securely via a server.

|

Checkweigher can also be connected with Enterprise Resource Planning (ERP) and/or Manufacturing Execution Systems (MES) and share actual production data.

|

| Risk of human error | Human error possibility very high. | Human error possibility significantly lower.

|

No human error possibility. |

It is clear from this table that whether a company is using a scale or a checkweigher, implementing SQC makes for faster and more accurate calculation of Standard Deviation. This delivers a more immediate identification of potential over- and under-filling issues, and consequent adjustment of production line equipment to reduce waste.

Benefits

There are benefits for food manufacturers across many levels of the business. Fundamentally, it provides better control over the quality of products they manufacture. Any unwanted trends towards under- or over-filling can be quickly rectified, saving wasted production. This benefit extends substantially into the realms of legal compliance, where SQC is a recognised tool for proving compliance to legislation such as European requirements for e-marking (net weight control), and weights and measures authorities. It delivers similar compliance benefits relating to regulations for Good Manufacturing Practice (GMP) or Good Laboratory Practice (GLP) in pharmaceutical manufacturing as laid down by the US Food and Drug Administration.

Manufacturers are required by law not to under-fill, to provide products that are safe for the consumer, and to keep detailed records around the areas of production quality and quantity that can be quickly made available for audit.

The commercial requirements of a food manufacturer’s customers may not have the same legal standing, but are critical nonetheless. Those customers can be reassured about the quality of the safety processes used in producing the product as well as the ability of the manufacturer to demonstrate legally-tight documentation and transparency around their processes, due to using SQC. If needed, the data generated in complying with higher legal requirements can also be used to prove to the customer that quality processes/standards have been adhered to.

The Financial and Environmental Protection Argument

The financial benefits of reduced waste and greater efficiency in production are another convincing argument for using SQC-enabled product weighing equipment, whether industrial scales or checkweighing. Over time, the money saved by reducing unnecessary overfill can help to pay for the investment in quality assurance systems. At the same time, accurate and precise use of raw materials means less waste, for a positive impact on the environmental footprint of the production process.

Nor are there great costs involved for manufacturers in equipping themselves with SQC, or indeed, utilising the capability they may already have in their existing weighing equipment software. Scales and checkweighers should be calibrated routinely, and calibration records made available for inspection. Routine maintenance on the machines must be upheld to ensure data accuracy, and operators trained to understand the importance of SQC data and the process adjustments that might be required because of it.

It is recognised that dynamic checkweighers represent a relatively high initial investment, albeit one that delivers a fast return, to allow high product throughput speeds with a highly reliable quality check that significantly reduces the risk of an entire batch loss. With these substantial initial costs in mind, an alternative approach is permitted by legislators, in which filling quantity checks can be carried out on random product samples of suitable size on an approved static scale. The advantage is the lower initial investment, especially since one checkweigher cannot usually be used for multiple filling lines. However, in the case of random sample checks, the operator is obliged to remove the entire batch if the random sample result does not comply with legal requirements. From a financial perspective, it is therefore a matter of assessing the initial high investment costs of a checkweigher performing advanced inspection capabilities, against the possible ongoing loss of entire batches during random inspections.

Production sites with multiple production lines operating at different speeds might opt for a combination of SQC static scales and dynamic checkweighers, with all data collected in a central database and FreeWeigh.net software monitoring overall compliance. With FreeWeigh.Net factories have the option to use standard scales, networked to collect weigh data from multiple lines and quality check locations, with data consolidated in one report and used for releasing the batch.

Summary

Manufacturers can decide what best suits their needs to measure filling weights in production. Whether implementing standalone scales, checkweighers, or combinations of the two, the use of SQC and FreeWeigh.net software improves their ability to identify and rectify filling issues at an early stage.

This is an important quality process that has an impact on production line efficiency, manufacturing costs, regulatory compliance, and environmental performance, and as such, the benefits of SQC-enabled weighing should be of interest to all food manufacturers.