A three-belt conveyor system was recently designed by YPS engineers to automate the shrink wrapping of small, lightweight e-cigarette packs.

An e-cigarette manufacturer approached the firm looking to automate the bundling process at the infeed of their packing process, in a bid to speed up production and reduce reliance on labour.

The system had to guarantee a neat seal every time, for varying product collations.

YPS supplied a fully automatic, servo-driven L-sealer to wrap the packs, but revealed it was the infeed conveyor arrangement that was specially designed to provide the level of speed and accuracy required.

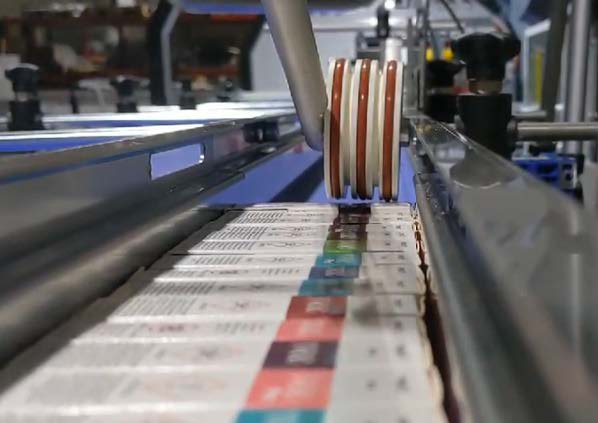

Three infeed conveyor belts were supplied, with individually controllable speeds. The first conveyor moved relatively slowly to allow a single operator to load the products in the correct rotation for shrink wrapping and the correct order for the desired collated packs.

A sensor located on the second conveyor would read when the final conveyor was full, with no gapping between products. This sensor would then release the final conveyor to rotate by a programmed amount, related to the number of packs required for the current collation, and push them into the sealer for the bundle to be shrink wrapped.

YPS added that changing the line configuration for a different product collation was a ‘simple case’ of changing the recipe at the intuitive operator interface. This would change the amount of rotation for the final belt, allowing bundles of anything between two and ten products to be pushed to the sealer.

The YPS engineering team implemented a system on the sealing jaw to guarantee the packs would pass through the sealing process without it activating, eliminating the possibility of damage to the packs.

The automatic l-sealer controls were paired with the shrink tunnel controls so all parameters could be accessed from the same user interface. The specially configured shrink-wrapping line produced a ‘neatly sealed’ product bundle each time and could be changed when different product collations were required.

“We look to work with our customers to understand their exact needs each time, so we can deliver a system that works precisely as they want it to,” said Glyn Johnson, YPS’ MD. “Our engineering team bring their experience and knowledge to any situation, however unusual, so we can find the right solution.”