MPE UK has launched a new machine designed to extend the shelf life of sandwiches.

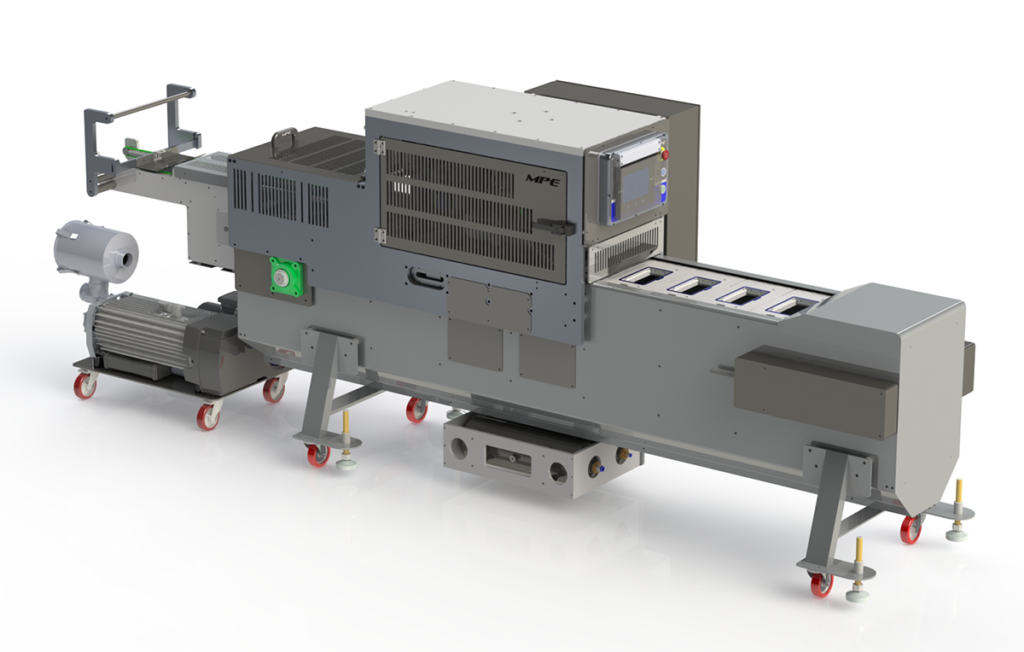

The SL1400VG is an inline heat-sealing machine described as being capable of increasing output for sandwich and lunch ranges for food shops and the catering trade as well as large-scale production facilities.

Suitable for sealing sandwiches with any sort of fillings, MPE said the machine provides a ‘consistently accurate’ seal and twin conveyors for speed, and can result in a shelf life of up to nine days.

The SL1400VG has a recipe-driven configuration system allowing for a ‘rapid’ switch of products which are loaded into the machine and indexed until they move into the seal station. The machine then modifies the atmosphere in the pack and hermetically seals the product, which is delivered onto a flat belt for final packing and transport.

Sealing up to 20 packs per minute, the SL1400VG is manufactured in the UK using stainless-steel construction and guarding.

MPE’s technical director, John Hodgkiss, said, “Our extensive experience of the tray-sealing industry means we can deliver highly versatile alternatives to the marketplace which are robust enough to be used in the toughest environments. We’re excited at what the SL1400VG can bring to the market.

“It’s a real game-changer, aimed at significantly increasing the shelf life of cardboard-packed sandwiches while still employing MPE’s machine design philosophy of a small footprint, simple to operate and maintain. Not only does this inline machine heat seal sandwiches and other lunch time products, it also increases their shelf life through MAP technology by longer than we’ve seen before in the market.

“The need for speed and accuracy is driving automation and innovation in the food industry, so we continually strive to provide exactly what our customers need to stay ahead of their competition and meet their own customers’ demands, as effectively and efficiently as possible.”