THERMOFORMED packaging specialist Charpak has set its sights on further growth in Scotland, with the spirits and whisky sector a “prime market”.

The firm designs and manufactures packaging solutions for companies operating in a range of sectors from food and drink to automotive and electronics.

Justin Kempson, Charpak’s sales and innovation director, told Packaging Scotland the business is keen to make further inroads north of the border. Charpak already has a number of major accounts in Scotland, including with Hamilton-based cake provider, Finsbury Foods.

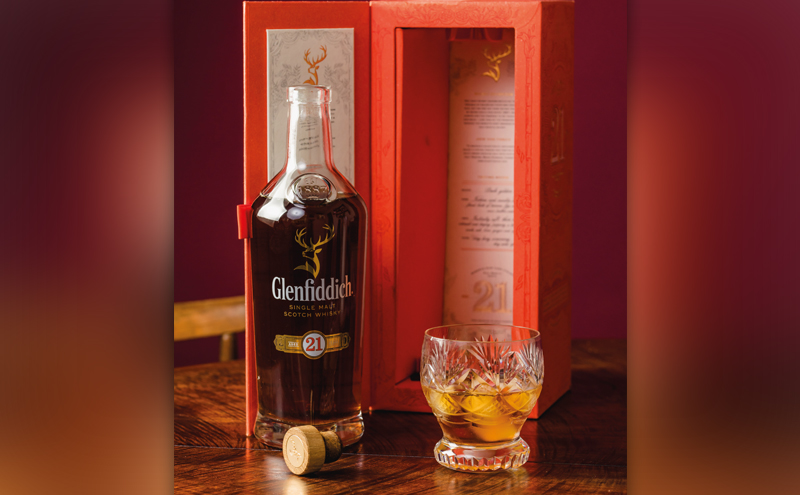

“The spirits and whisky sector is a definite market for us,” Justin said. “Historically we have done a fair amount in the value added packaging end of the spirits industry. We work closely with other suppliers and work with them to develop concepts for that industry.

“It’s certainly the premium sector we have to be looking to in the future because that’s where the export market should be with spirits. It’s about adding value to the product.”

Justin stressed the importance of innovation when it comes to premium drinks. “There has to be innovation; there has to be new concepts,” he explained. “Packaging is there for two reasons: one is to protect the product and the brand; and the other – which is more important from my point of view – is to sell the product. We don’t experience the physical product until we buy it. What attracts us to it is the aesthetics and the way it looks. Does it look good? Do we want to buy it? Yes we do. If it’s a great product, we’ll go back and buy it again. That first key purchase is about what it looks like; that’s what packaging does and where Charpak deliver.”

Like so many firms involved in the packaging supply chain, much of Charpak’s attention this year has been focused on sustainability following what Justin described as the “demonisation” of plastics.

“Charpak as a business is looking outside of plastics and what else we can utilise our machinery to do,” he added. “There could be more biodegradable-based products. There are good moulded paperboard options; Charpak is certainly investigating that. We’re looking into naturally degradable products. Realistically, with the demonisation of plastic, it’s about the next big thing. You have to be ready for that.”

Justin isn’t prepared to give up on plastic though. Instead, he wants to move the conversation away from waste and instead focus on recycling.

“There is a huge amount of plastic that already exists, and actually we’re far better reusing that, so let’s change the narrative from throwaway plastics to reusable, multi-use plastics,” he commented. “We are progressing a local closed-loop partnership.”

Justin explained the firm has teamed up with both a waste contractor and reprocessor in Cambridgeshire to re-use kerbside-collected plastic waste.

“We’re founder members of WRAP’s The UK Plastic Pact, as well as a member of RECOUP ” he added. “We’re reusing plastic rather than creating new plastic. If we can get to a situation where 90% of plastic is re-circulated, from a fossil fuel perspective we’d only be adding 10%. We can then change the narrative from single-use plastics in general terms, to multi-use plastics used again and again. It doesn’t matter what it’s used for next time. It could be a bottle today, a plastic tub next week and a tray for the whisky industry in six months time. Why would you not want to do that?”

Justin said the two things Charpak invests heavily in are people and machinery. Some £2 million has been spent over the past three years on “faster, more efficient” machines, while there’s an ongoing focus on recruiting the right people to design innovative products.

“From a machinery point of view, we’ve invested very heavily, which is about providing the product at the right time and the right price and having the capability to do more and more with the plastic. That type of investment is vital for us. In terms of innovation of product, we’re constantly doing that. We can do things with plastic other people can’t, some of which is commercially confidential. We’ve devised a system to create 3D cakes. That is primarily for Finsbury Foods in Hamilton because they have licences with Disney Pixar and those types of companies.

“A recent example is a 3D cake for the Jurassic World movie, featuring a T-Rex. The cake is baked in 3D shape, which brings a labour saving, a food saving, less waste – and it’s a fantastic cake!”