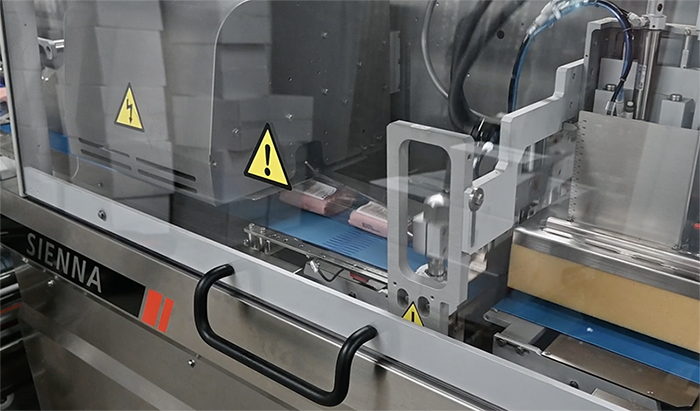

ULMA Packaging has supplied Albion Pet Foods with a SIENNA flow wrapper (HFFS), following the company’s decision to establish an in-house manufacturing facility in Warwickshire.

The SIENNA’s feeding mechanism, situated underneath, automatically aligns products on the conveyor, which ULMA explained ‘significantly’ boosts efficiency and reduces manual labour. This feature meets Albion’s objectives to increase production to satisfy growing market demands.

The model’s intuitive design is also said to ensure ‘seamless’ production flows and simplify staff training.

Giles Bower, MD of Albion Pet Foods, said, “ULMA’s SIENNA flow wrapper has not only streamlined our packaging process but also reinforced our commitment to delivering the highest standards of pet food products to our customers. Its automated feeding mechanism and robust performance align perfectly with our goal of embracing innovative solutions for sustainable growth.

“We’re confident that this investment will play a pivotal role in shaping the future of Albion Pet Foods, allowing us to meet the evolving needs of our market with greater agility and reliability.”

ULMA Packaging’s James Couldwell added, “Our work with Albion Pet Foods exemplifies ULMA’s dedication to delivering packaging solutions that not only meet, but exceed our clients’ expectations in efficiency and quality. The SIENNA flow wrapper embodies our commitment to innovation and reliability, and we are delighted to see its significant impact on Albion’s in-house manufacturing processes. This partnership highlights our continuous efforts to support businesses in achieving their production objectives and sustainability goals.”