OMRON has announced that a single demonstration line on its stand at this year’s PPMA Total Show will reveal how a ‘dynamic’ manufacturing operation – in this case filling – can see efficiency and uptime improvements from the deployment of AI.

The manufacturer will show benefits in intelligent machine control and fault detection and remediation.

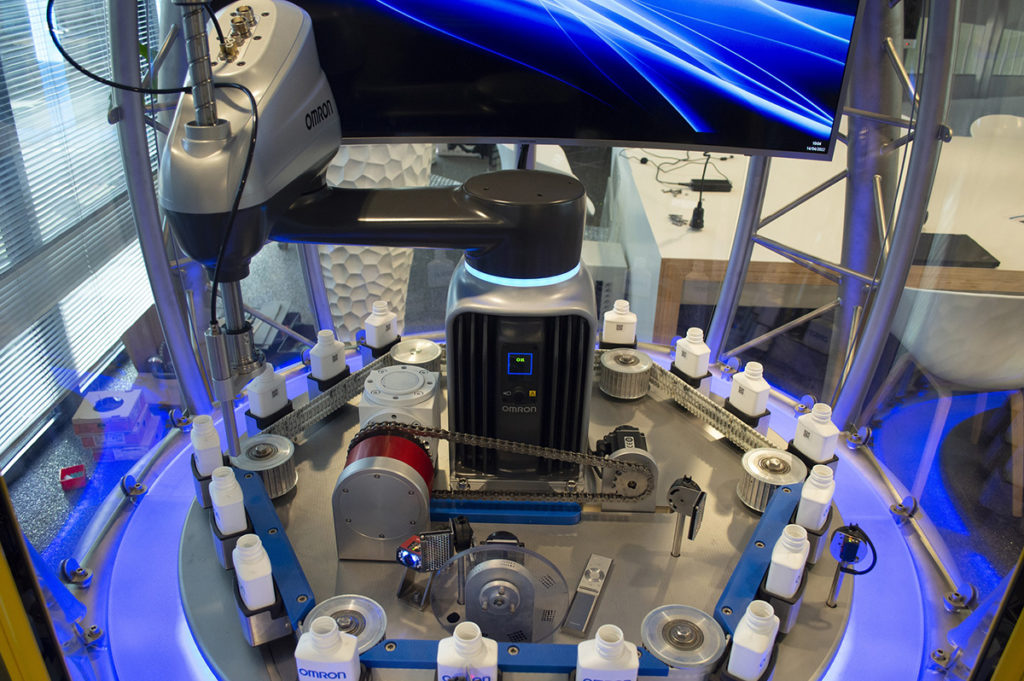

Omron explained that too many operations gather large amounts of often unusable data, which requires analysis before it can be acted upon. The first of the firm’s two areas of digital intelligence is focused at machine-level, through its Sysmac controller with edge-based AI. With filling handled by an i4 SCARA robot, the small bottling line will demonstrate how this technology can deliver real-time trend analysis and alerts ‘on the fly’.

“The first step is to work in partnership with the customer to establish what data is being extracted from the line, cut out the ‘noise’ and focus on actionable data,” said Omron’s UK marketing manager Stuart Coulton.

This live ‘data-at-the-edge’, combined with the controller’s adaptive intelligence, allows the system to flag up anomalies. Depending on operational priorities, these could relate to things like fill level, visual defects or mechanical properties. Any deviation outside a defined window can be pre-set to trigger a visual alert, alarm or even – in the case of safety-critical variables – line shutdown.

During lockdown restrictions, equipment users have often had to resort to remote digital troubleshooting. Omron said that in the second area of applied AI to be demonstrated in Birmingham, it will show how it has recognised the strengths of this approach, and formalised them within an advanced services offering based on the use of augmented reality (AR).

“Using AR glasses, in-house engineers can work with a remote expert to correct any machine malfunction they cannot diagnose or remedy themselves,” Coulton added. “Downtime – and especially unplanned downtime – has always been a bugbear for manufacturers.

“Omron’s solution helps to dramatically minimise that impact. Many businesses will also be conscious of the carbon footprint savings, as well as time efficiency, resulting from this use of technology.”