ISHIDA has announced that its stand at this year’s PPMA Total Show will feature solutions from the manufacturer’s multihead weigher, checkweigher and X-ray inspection system ranges.

Experts will be on hand to discuss specific customer projects and challenges and outline Ishida’s capabilities in the design and installation of fully integrated packing lines.

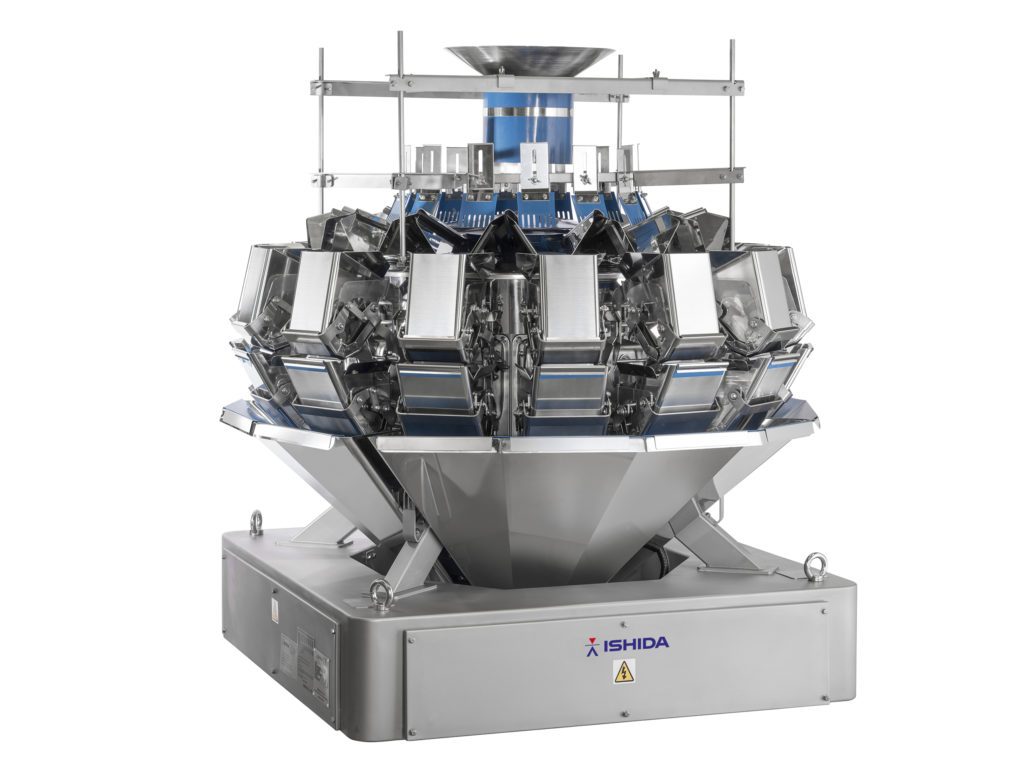

Two models from Ishida’s range of multihead weighers will be featured. The 14-head CCW-RV-214W-GS is designed to weigh fragile products such as biscuits and confectionery, while the six-head CCW-R2-106WB Fresh Food Weigher (FFW) has been produced to handle sticky fresh and bruise-sensitive products.

The CCW-RV-214W-GS uses ‘gentle’ slopes and reduced angles to ease the passage of products. In particular, Ishida explained that the curved hopper design creates controlled decelerations that allows product to roll and settle gradually, minimising breakages.

The CCW-R2-106B FFW provides a semi-automatic solution is said to be particularly suitable for factories with height limitations. The weigher can receive product from a conveyor belt to the top of the weigher, where one or two operators distribute it via belt feeders to the weigh hoppers. The ergonomic layout, Ishida added, makes it easy to spread out products on the feeder table and the belt feeders facilitate a ‘precise and consistent’ product feed to the hoppers.

The firm’s quality control solutions will be represented by the IX-EN-4093-S, an entry-level X-ray inspection system that Ishida said combines ‘impressive sensitivity with minimal operating costs’ and the DACS-G-F015 checkweigher, developed in particular for high-speed production lines.

The IX-EN-4093-S incorporates Ishida’s Genetic Algorithm (GA) image processing technology. The manufacturer revealed it can detect foreign bodies including steel, aluminium, tin, glass, stones, dense rubber, plastic, bones and shells. The system can also carry out additional quality checks such as identifying damaged or missing items, weight estimation and counting components.

The DACS-G-F015 checkweigher with integrated metal detector uses the company’s Force Restoration weigh cell. The machine’s Force Limiting Disconnect feature is said to prevent damage to the weigh cell and extends machine life. The checkweigher is fitted with Ishida Retail Reject Confirmation (RRC) to help food manufacturers meet the latest retail codes of practice.